It begins with a client who demands the opportunity to make real design decisions regarding her or his building or fitout project. Already, this is unusual. Most people want to be protected from minutiae and don’t mind living in a building or fitout they don’t understand, can’t talk about and can’t love.

It develops with a comprehensive design dialogue facilitated (as required) by drawings, models, visuals, feasibility studies and costings. In our internet age (sigh), this normally starts not as it might with an appreciation of architectural, natural and human features in the immediate surrounds, but with images selected by a Silicon Valley bot that knows or cares nothing for a built environment arising out of traditional (often ancient) farming, fishing and mining lives in Cornwall and Devon.

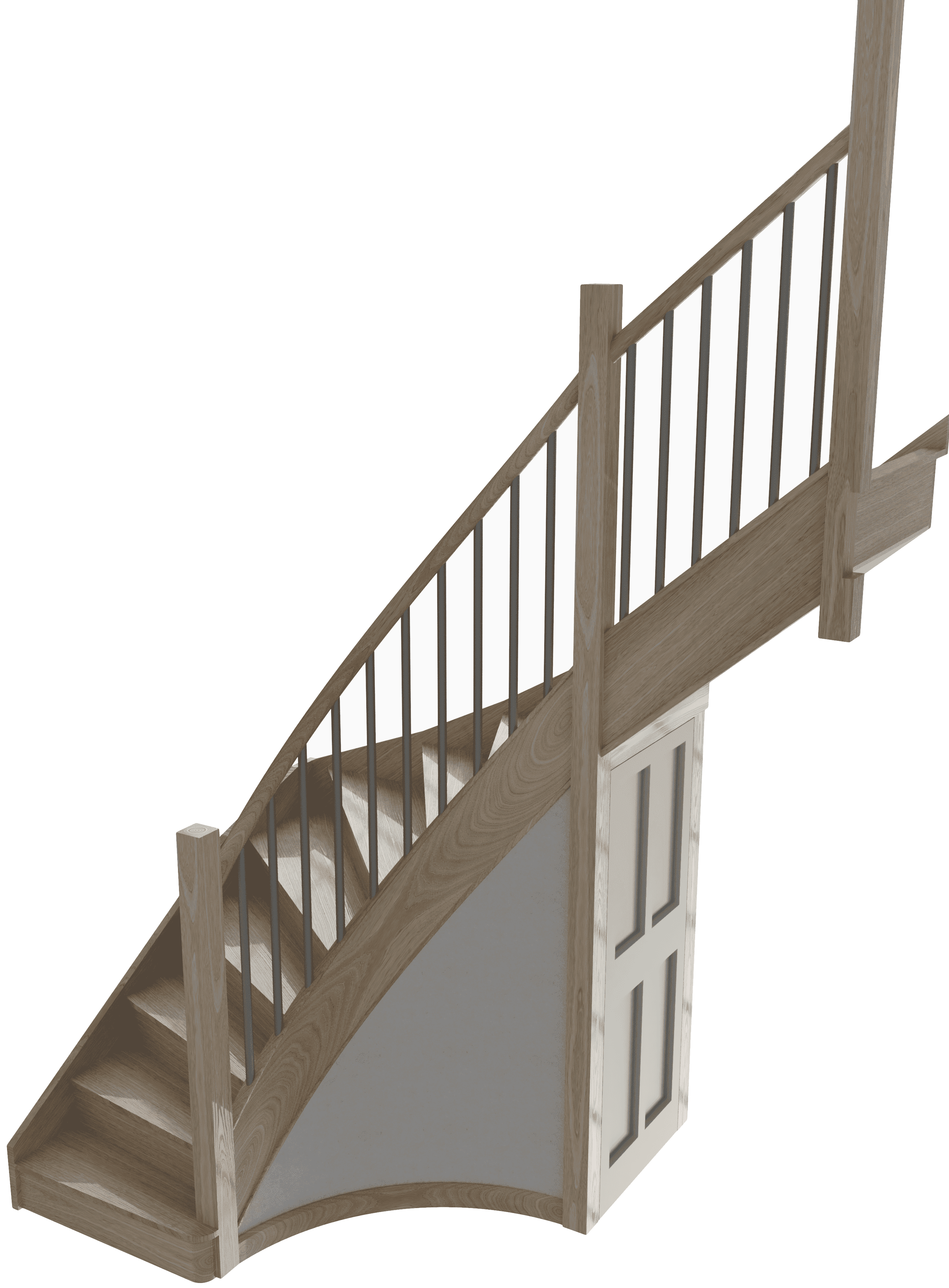

It reaches client-approved drawings that communicate both design intent and feasibility to any builder or manufacturer. Getting to this stage can cost anything from £200 for a straightforward single piece to £20,000 for a complex structure or fitout. I can leave the project at this stage or remain involved to bring added value and coherence to the build / manufacture process.

I use software from the AUTODESK Product Design Suite, mainly AutoCAD, Inventor and Fusion 360. Accordingly, files lend themselves to manufacture by CNC machines and 3D printers. I’m also able to extract cutting lists which are not just extremely useful to manufacturers; they enable small, low-tech and low-overhead outfits to outsource high-tech aspects of any project. The results can be the best possible examples of lean bespoke manufacturing.